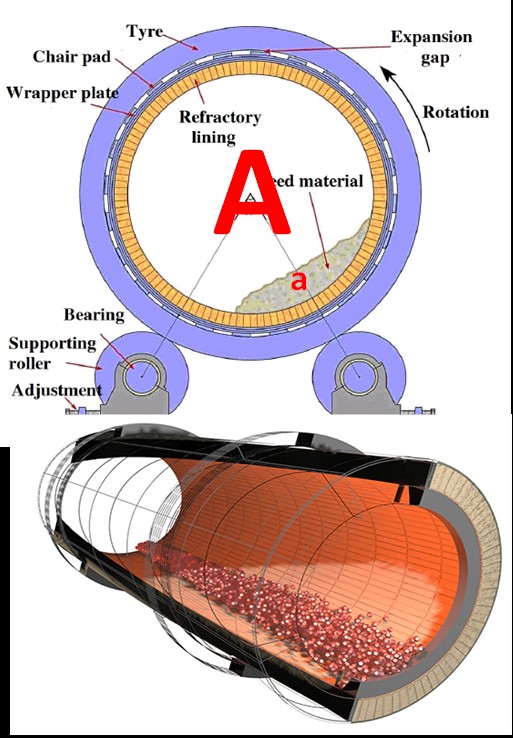

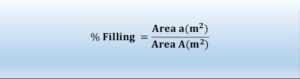

Kiln Degree of Filling (% Filling).

Degree of filling is defined as the ratio of area/volume occupied by material to the area/volume empty. Kiln filling % signifies the ease of heat transfer between flam and kiln walls to kiln feed. In long kiln designs and SP kilns the kiln speed was generally low due to heavy calcination load on kiln. therefore, it was recommended to keep kiln filling degree on lower side. But in modern calciner kilns calcination duty is almost completed before feed enters kiln, higher kiln speeds are possible. which has improved heat transfer quite significantly. and therefore as higher as 17 % of kiln degree of filling is common in modern calciner kilns.

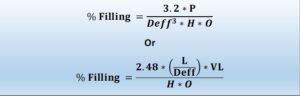

Various formulas are used to calculate percent filling, we will use FLS formula as under:

Where P=kiln production(tpd), Deff=effective diameter, H=Kiln Slope in %, O=kiln speed in rpm, VL=volumetric load.