In the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Pre-homogenization and raw milling, and has not been discussed separately by most of the authors. However, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is considered. After monitoring and controlling the quality of incoming raw material, the area of high activity for quality department to ensure quality mix for smooth production of high quality of cement is “mill feeding system”. The system consists of material hoppers/bins, weighing, conveying, venting and mill feeding gate.

Mill Feeding Hoppers

Hoppers for limestone/ clay/ iron ore serve the purpose of providing a buffer storage for mill feed and a convenient arrangement for feeding to weigh feeders for proportioning purpose. Hoppers used to be designed to hold the requirements of one shift. However, with raw mill capacities reaching 250-700 tph it is no longer practical to do so. Further with reclaimer belts of stacker reclaimer system running round the clock it is as well no longer necessary to do so. Thus hoppers may be designed to hold only 4 hours' requirements. On the other hand, requirements of clay/silcastone, iron ore are very low that hoppers to hold 8 hours' needs are too small. Therefore, for practical reasons hoppers for them would be designed to hold about 24 hours' needs; but seldom more because of sluggish flow of these materials in hoppers. Whatever capacity and geometry you may be having in existing plant or planning to have in proposed plant, we need to be careful to check that the material segregation is minimum and that the disturbances by virtue of this phenomena are negligible.

Hoppers can be in steel or in R.C.C. For small capacities, steel hoppers would be preferred. Hoppers for raw materials can either be rectangular or circular in shape. A circular cone is preferred as it eliminates valley angles and consequently improves material flow. Having rectangular or square shape at the top and changing to conical at discharge creates shelves at junction, where material accumulates, which causes problems of flow of material in extraction. Cone surfaces can also be lined with special liners with smooth surface. For wet materials cones at outlet are heated with heating pads in more difficult cases and are fitted with vibrators in others. In any case even for free flowing materials, the angle of cone should never be less than 50 degrees to horizontal. Bag filters are generally installed at the top to vent air when material is fed to a hopper.

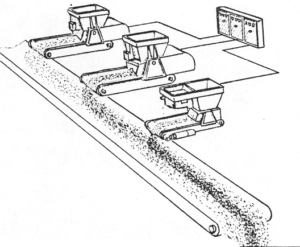

Mill Feeders: Feeders for raw mills will be directly installed under hoppers with rod gate in between. The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill. Feeders for mills meter feed rates and also totalize tons fed. For raw mill feeding, table feeders, belt feeders, and weigh feeders have been used. However, weigh feeders are the most commonly preferred feeders for limestone, clay and iron ore.

Mill Feeders: Feeders for raw mills will be directly installed under hoppers with rod gate in between. The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill. Feeders for mills meter feed rates and also totalize tons fed. For raw mill feeding, table feeders, belt feeders, and weigh feeders have been used. However, weigh feeders are the most commonly preferred feeders for limestone, clay and iron ore.

Metering on Feeders

Metering can be either direct (gravimeteric) or indirect (Volumetric/impact). In direct method of metering the material passes over a load cell installed in weigh feeder/apron feeder and the travel speed is monitored with installed tachometer. Weight and speed together determines the mass flow rate of material in metric tons per hour (t/hr). Alternatively, in some of the arrangements direct system consists of weigh feeder and its pre-feeder. Feed rate is generally controlled with the speed of weigh feeder belt, which is driven by a variable speed drive. Feed rate is monitored and controlled by a control panel generally supplied with weigh feeder. Set points are passed to control panel from CCR by Operator manually or through Quality controlling software like QCX. In indirect metering system feed rate is determined by measuring cross section of material and rate at which it flows and taking into account bulk density of material.

Calibration and Drop Test Facilities

Provisions for drop test for calibration of weigh feeders are commonly available in cement plants to validate production figures. Although the weigh feeder calibration is not required frequently unless there is a disturbance in mechanical system due to various reason including maintenance. However, it is a common practice to validate feed rate through drop test periodically. Weigh feeders generally come with self-calibration devices. A simple way of 'self-calibration' is to have the hopper mounted on load cells, so that a weight loss for predefined time will be used for calibration purpose, and in this case calibration of hopper load cells needs to done at least once a year with standard weights.

Metal Detector and Magnetic Separator

Arrangement of metal detector and magnetic separator is integral part of feeding system in vertical roller mills and roller presses. Both are installed on mill feeding belt conveyor. Magnetic separator, separates out small metallic impurities from mill feed. While as metal detector signals the presence of metallic debris, which can damage the grinding path and give rise vibrations issues. For ball mills, the installation is not considered generally necessary, however the installation of above instruments can avoid occasional tripping due to jamming of rotary gates at mill inlet due to metallic debris from various origins as well as helps to reduce metallic nibs accumulation in mills, which disturbs mill operation and mill discharge material transport through air slides.

Cold Air Locking at Mill Inlet

This is very important, particularly in the situation when the moisture content of raw material is on higher side and the deficiency of hot gas in mill can effect on mill throughput or reduce mill outlet material temperature below 80 oC. Rotary feeders (gravel gate), double flap valve are used to stop/minimize cold air leakage into mill system. Cold air leakage percentage can be determined by measuring oxygen percentage in kiln hot gas at mill inlet and mill outlet.