Volumetric Loading of Kiln (VL).

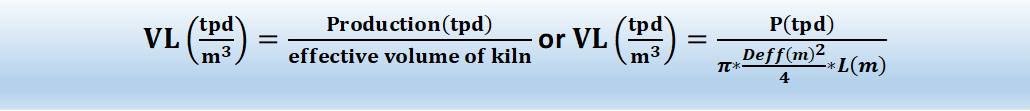

Volumetric loading of kiln is defined as clinker produced in tons per cubic meter of kiln effective volume per day.

Volumetric loading provides an assessment of potential capacity of kiln in given kiln system.

Before giving you formula to calculate volumetric loading, let us understand some basic terms regarding kiln geometry.

L/D Ratio.

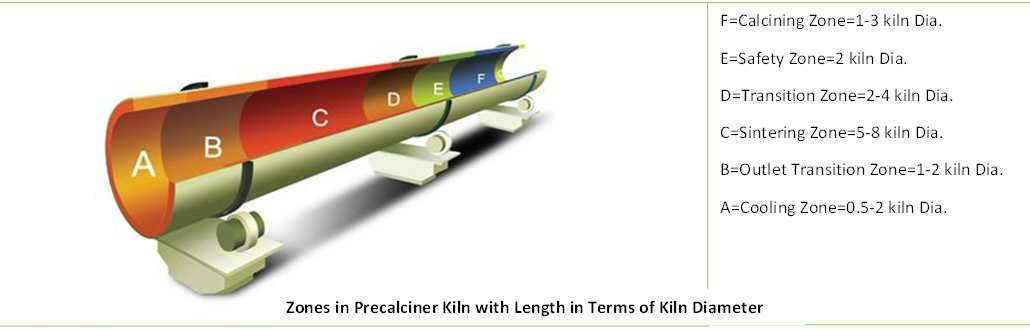

With the development of cement manufacturing technology, the length of kiln has reduced significantly relative to kiln diameter. From 40 to 11 L/D ratio in long wet kilns and modern two tire kilns, L/D has a special significance in cement plant. Moreover, this dimensionless number is used commonly in engineering practices in design of any transport and processing systems. It has been a general practice to represent lengths of various zones in kiln in terms of multiplier of kiln diameter as below.

Effective Diameter of Kiln Deff .

Effective diameter is the diameter available for actual manufacturing process. For most of the process calculations it is used as kiln diameter.

Here effective diameter and total kiln length is used to calculate volumetric loading of kiln as under.

Where P= clinker production in 24 hours, Deff=kiln effective diameter in meters, L= kiln length in meters.

Volumetric loading of some of the common kiln systems is tabulated here.

| Volumetric loading for various kiln systems | |

| Kiln System | Volumetric Loading tpd/m3 |

| SP | 1.8-2.3 |

| ILC-E | 1.8-2.5 |

| ILC | 3.6-4.8 NORMALLY 4.5 |

| SLC | 3.6-4.8 NORMALLY 4.5 |

| SLC-I | 3.6-4.8 NORMALLY 4.5 |

| SLC-S | 3.6-4.8 NORMALLY 4.5 |

| SLC-D | 3.6-4.8 NORMALLY 4.5 |

| ROTAX | Max 5 +0.3[3.6-CaOfree at 1400oC] upper limit 5.3 |

- Same size kiln with calciner will give double clinker production compare with SP kiln.